In an era of modern manufacturing, process automation, Industry 4.0, IoT, AI, and more, the need for innovative solutions in workholding and manufacturing innovation has never been greater. For over 130 years, Hardinge has been perfecting its manufacturing processes to satisfy the growing needs of an industry that must always stay one step ahead of every trend globally, and the company has been investing heavily in constant optimizations to remain the global leader in machine tool technology.

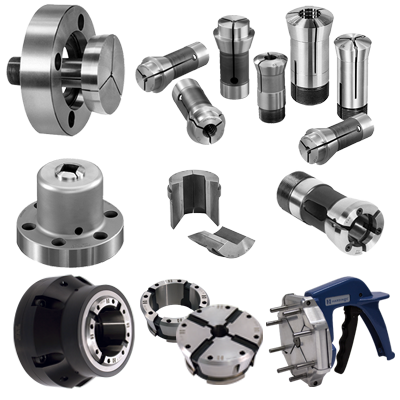

To meet with the demand of higher-precision parts, reduced lead times, and lower production costs, Hardinge is leading the way with the next generation of machine tool technology. Here are just a few ways in which Hardinge is pioneering the next generation of workholding technology at its Elmira, NY facility:

- Live Machine Reporting:

Machine Metrics software has been implemented on our Swiss production line, providing live machine performance tracking that allows operators and management to see how they are performing in real-time to get the best utilization from our equipment. This practice, once proved on our Swiss production line, will be rolled out to the remainder of our workholding manufacturing operations.

- New FlexC Product Offerings:

The FlexC family will be expanded to include three new product sizes by the end of March 2023 to better serve the growing needs of our customers.

- Exploration of Hard Turning Operations:

We are actively evaluating the prospect of introducing hard turning operations into the Specials area to combine or eliminate multiple grinding operations wherever possible, greatly reducing lead times for our customers.

- Combining Turning and Milling Operations:

The R&D team is investigating opportunities to combine turning/milling operations into one operation that will eliminate set-ups and waiting time between operations, further improving the efficiency of the overall operation.

- Automation of Heat Treat:

We are in the process of completely automating our heat treat facility. With this automation, the operation will see huge improvements in the areas of both safety and process control, ultimately improving repeatability and bringing maximum quality to our customers.

These key innovations, along with countless more, will work to ensure that Hardinge remains the definitive global leader in machine tool solutions—and will propel the industry well into the next generation of advanced manufacturing. With these practices, Hardinge is excited to lead the machine tool industry into a new era of advanced manufacturing. To shop our best-in-class workholding solutions, click here.

About Hardinge, Inc.

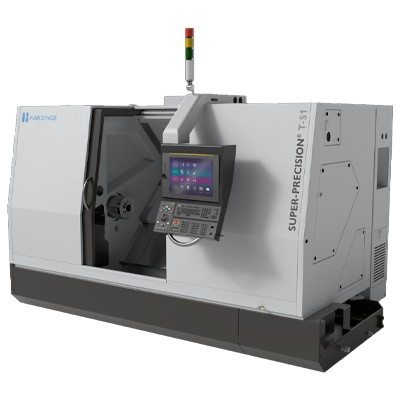

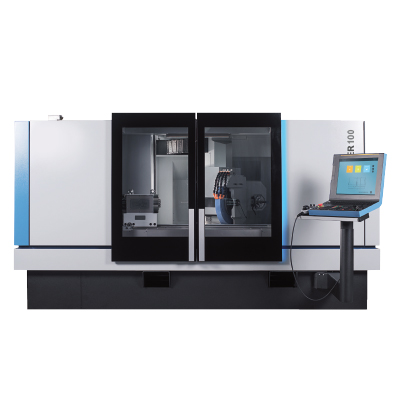

Hardinge Inc. is a leading international provider of advanced metal-cutting solutions. Headquartered in Atlanta, GA, Hardinge Inc. offers a full spectrum of highly reliable CNC turning, milling, and grinding machines as well as technologically advanced workholding and machine tool accessories. The Hardinge Group has developed a strong global presence with manufacturing operations in North America, Europe, and Asia.

Contact: Ryan Ervin

Chief Marketing Officer & Vice President, Sales

607-378-4052(o)/607-425-6997 (c)

Ryan.Ervin@Hardinge.com