We are excited to introduce our NEW Bridgeport® V-1320 Vertical Machining Center. It is an addition to the Bridgeport V-series Vertical Milling center line, and it is the best overall working cube in its class, offering a high quality, rugged and powerful machine center developed for tough machining applications that is well suited for high speed and hard metal cutting conditions.

“The V-1320 is a state of the art Advanced Performance CNC Machining Center at the top of the Hardinge Milling product line. Our machine centers provide not only highly accurate and precision detailed parts in the aerospace and medical industries but also the robustness to handle the demanding day to day operations in the automotive industry.” – Michael Marshall, Hardinge’s Global Milling Product Manager.

Bridgeport® V-1320 Vertical Machining Center

The new machine is a fully digital, high-quality machine tool, designed to achieve maximum capacity and performance in the job shop, OEM, aerospace, automotive, energy and other demanding markets. V-1320 features include:

- Dual Y-axis ballscrews for improved surface quality and roundness accuracy, acceleration, reduced vibration, and increased tool life.

- Easy and intuitive to use with new Touch screen control – Equipped with a 15” Mitsubishi M80 Color LCD touch screen, users can intuitively control the machine. Pinch to zoom in and out, scroll through screens, move pop-up windows on the screen, or drag with a single finger. The M80 also will come standard with two 32 Gb SD card slots for memory expansion, USB program running, high accuracy modes and super smooth surface software.

- Provides superior machine accuracy and repeatability with dual ballscrews – the V-1320 comes complete with oversized high-class 45mm double nut Ballscrews, fixed and pre-tensioned and large 45mm Linear high-quality linear guideways supported by 6 trucks on the X and Z Axis. Dual 40 mm ballscrews on Y Axis.

- Confident cutting with a powerful spindle motors – The new V-1320 has a Big Plus, 40 taper, 12,000-rpm Direct Drive spindle powered by a dual-wound Mitsubishi spindle motor. Quad set of 70mm angular contact bearings and a 60mm rear taper roller bearing provide superior thermal stability, significant radial and axial stiffness and high accuracy as well as 900 kgf tool retention for aggressive cutting applications.

About the Bridgeport® V-Series

The Bridgeport® V-Series Vertical Machining Centers are new generation machines. These machines are digital, high- quality machine tools, designed to achieve maximum capacity and performance in the Job Shop, OEM, Aerospace, Automotive energy and other demanding markets.

Bridgeport® V-Series machines have an exceptional combination of features for speed, power, accuracy and durability in a compact design and affordable price. They are rigid and reliable machines consisting of a robust, one-piece cast iron base, heavy-duty linear guideways and ballscrews, and many value-added standard features such as:

- heavy-duty dual-wound spindle motor

- 40-psi coolant supplied through circular flushing

- coolant ring at spindle face offering 360 degree

- coverage of the cutting tool

- chip conveyor interface

- swing-out CNC control panel

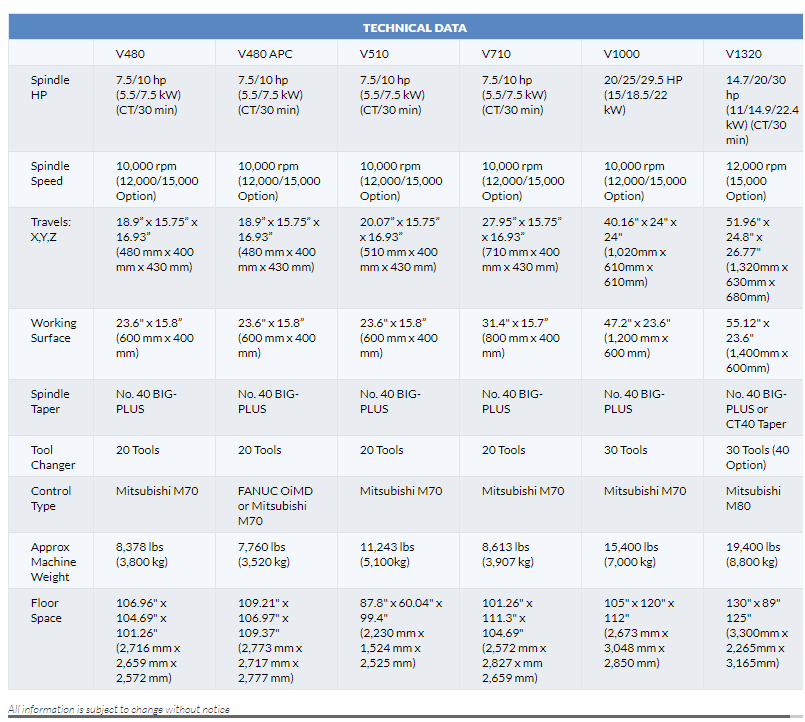

Choose from the numerous productivity options and you’ll have a truly versatile machine—with the level of quality you would expect with any Bridgeport® product. The following chart provides an overview of the technical features of each solution in the Bridgeport® V-Series product line.

Learn more about the new Bridgeport® V-1320 Milling Center