High precision parts, often constructed from advanced materials, are used in some of today’s most demanding industrial applications. The medical, aerospace, and automotive sectors depend on complex parts machined with near-perfect tolerances. Many of these components are tiny with intricate designs; part sizes usually range from 0.020-1.25”, averaging 0.75”.

It’s difficult to produce large volumes of these high-precision miniaturized parts, especially with small diameters, with standard CNC equipment. Instead, companies often use a Swiss-style CNC machine, distinguished by feeding stock through a guide bushing while the cutting tool remains fixed. The workpiece is held steady and supported by the guide bushing throughout the machining process, while a tool cuts the stock right next to the point of operation. By reducing vibration and deflection, Swiss-style machines enable shops to quickly and accurately produce long, slender parts and tiny, odd-shaped, or other hard-to-machine pieces.

Swiss Style Collets are the Key to High Precision

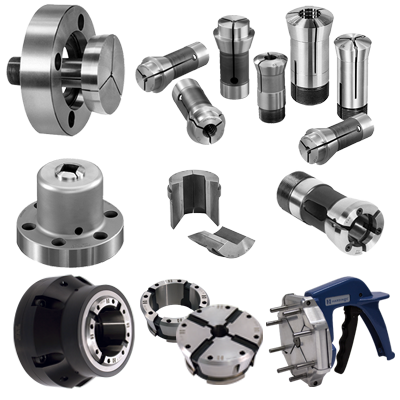

To derive the most value from a Swiss machine, you need a proper workholding that can capably support high-precision machining. Because of the importance of accurate guide bushing positioning and spindle performance, the performance and quality of these tools are essential to process stability. The workholding device must keep the workpiece completely stationary and clamp it very firmly. It’s the rigidity of this process that significantly reduces or even eliminates chatter, further improving workpiece stability and ensuring high-quality results. In Swiss-style machining, the workholding devices must work smoothly and in tandem to provide the proper results. Workholding can affect the parts’ accuracy, tool wear, and productivity levels, and their quality and reliability are paramount. Collets are frequently used as a holding device in metalworking applications, including Swiss machining. Offering greater gripping force and precision than a chuck, high-quality collets exhibit strong clamping force, high precision centering, and the ability to resist loosening. To produce accurate, intricate parts that meet industry standards, you’d need a burr-free collet with guaranteed concentricity, like the ones manufactured by Hardinge.

Reliably Delivering Industry-Leading Swiss Workholding Tools in Just Days!

An innovative producer with over 130 years’ machining experience, Hardinge offers an unmatched selection of high-quality workholding tools for all brands of Swiss-style machines and cam-operated lathes. We offer a complete line of tool holders, tool holder collets, tap holders and workholding collets and guide bushings used on Swiss-type machines from manufacturers such as Nomura, Star, Tornos, and Tsugami. Our family of Swiss-style collets is extensive and includes various styles, including headstock, pickoff, toolholder quick-change tap emergency and extended nose emergency, and bar loader collets.

We also manufacture bar feed collets for other vendors’ bar feeders. Visit https://shop.hardinge.com/ to see what we have available.

Swiss Quality Made in America

Our Made-in-America tool holders, working collets and guide bushings are manufactured to Swiss quality. For example, our collets provide a smooth and concentric gripping area (order hole) for the bar stock or workpiece. Offering unmatched availability and delivery speeds, Hardinge’s most popular TF20 and TF25 Swiss collets are shipped and delivered in an industry record-breaking 1-2 business days!

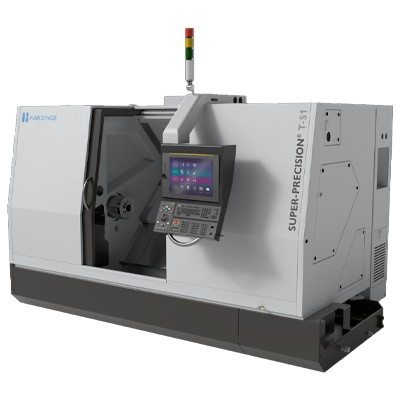

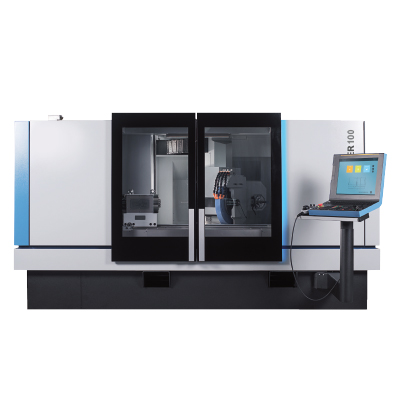

Our dedicated team of highly skilled machinists uses top-of-the-line equipment combined with industry-leading material and heat treatments to produce workholding tools of exceptional quality and durability. Our Swiss-type collets are manufacture to rigid specifications and hard turned to precise size and TIR to achieve exacting accuracy and meet high precision machining requirements. We inspect each collet and guide bushing on a Hardinge Super-Precision (. 000015″ TIR) headstock before it reaches the stockroom and ships to your company.

All our products are hardened and hard turned to ensure maximum life during high-production machining on Swiss-type lathes to solve common machining problems. For example, our round Swiss Bushings are carbide-lined to keep stock clean and unmarked.

Special Orders are our Specialty

Hardinge can custom build specialized collets, guide bushings, or related workholding devices tailored to your specifications or nonstandard Swiss-style machining applications. We offer specialized guide bushings in hardened steel, Meehanite lining, angular and zig-zag slotted and extruded shapes. Our custom workholding engineers and support staff will work directly with you to produce a made-to-order collet that addresses your unique Swiss turning and production requirements. We design and produce customized collets quickly and with great attention to detail. Some common examples include special-accuracy collets, radius and off-center order hole collets, and closers. Like all our workholding devices, we manufacture our specialized collets to the highest accuracy and quality standards. Whether you need to process odd-shaped parts, perform off-center turning, or some other technical application, our custom collets can handle the job.

Call (833)-COLLETS today to speak with one of our Swiss Workholding specialists and learn more about Hardinge’s best-in-class collets and how quickly we can produce and deliver them.

Hardinge, Inc. is a global leader in designing, manufacturing, and distributing innovative, precise, advanced metal-cutting machine tool solutions for the most demanding applications. We provide a full spectrum of highly reliable and accurate CNC turning, milling, and grinding machines, as well as technologically advanced workholding and machine tool accessories. Click here to learn more about our extensive Swiss collet product line.