Machine Inventory Sale

Exclusive, limited-time offers on precision CNC turning centers, milling machines, grinders, multifunction turning/grinding machines, and more. Act fast: all machines are in-stock and ready to ship!

IMTS Demo: Hard Turning of Carbide Draw Die

The Industry: Carbide Dies & Tooling

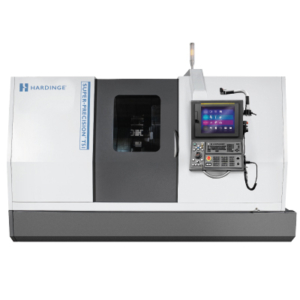

Turn/Grind SUPER-PRECISION demonstrating hard turning of carbide draw die with single setup. Carbide is used heavily in the canning, bullet, punch, and other precision machining applications across the globe. Traditionally intricate profile and radius requirements were reserved for more costly and complicated manufacturing techniques. With the demand for Carbide dies spiking globally manufacturers are looking for more efficient and cost-effective solutions to install.

The Industry: Aerospace, Medical, & Automotive

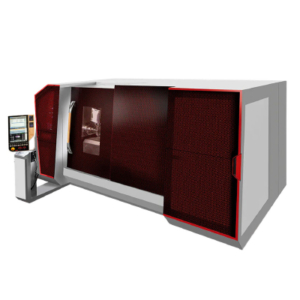

The ARTERY manufactures first class surfaces and enables maximum space saving through the DIRECT-WALL-CONCEPT. Available as a highly efficient 5-axes precision turning machine and as turnmill center for autonomous, highly precise and cost efficient 6-sided complete machining.

IMTS Demo: Muzzle Break, completed in one operation from bar stock

The Industry: Firearms Manufacturing

With higher demands on manufacturers to increase output due to consumer consumption of firearms, they are looking for ways improve throughput, efficiency with cost effective solutions.

The Industry: Automotive

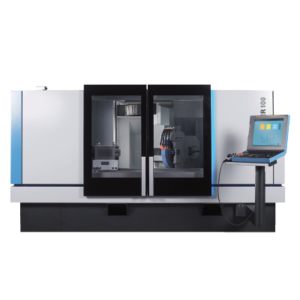

The UNIVERTOR AS series offers outstanding manufacturing competence for workpiece applications at highest productivity, continuous accuracy and finishing precision. Numerous equipment options enable the ideal solution for customized manufacturing requirements. Whether medium or large series, whether light or heavy, whether aluminum, cast iron, steel or titanium, whether dry or wet machining- independent of the production taskset, the UNIVERTOR AS covers a wide range of applications.

IMTS Demo: Spherical Bearing with Modified Form

The Industry: Carbide Dies, Tooling Bearing, & Injection Mold

This is meant for any industry that strives to develop parts with exacting contour details.

The Demo: Auto Racing Hub

The Industry: High Performance Automotive & Racing

Automotive performance manufacturers look to be efficient, whether in day-to-day production and competitive racing components. The Talent TT51 provides this solution in completing components in single setup applications with its dual turrets and sub spindle configuration.

IMTS Demo: Hard Punch

The Industry: Harden Tool Steel & Tooling

Hardened tool steel is used heavily in the canning, bullet, punch, and other precision machining applications across the globe. Traditionally intricate profile and radius requirements were reserved for more costly and complicated manufacturing techniques. With the demand for harden tool steel punches spiking globally, manufacturers are looking for more efficient and cost-effective solutions to install.

IMTS Demo: Mill Spindle

The Industry: Machine Tool Building

When building a machine tool, whether it’s a turning, milling, or grinding machine, the spindle is a major critical component for accuracy. Surface finish, roundness, and tight diameter tolerances go hand in hand when making a precision spindle. Hardinge has been relying on Kellenberger grinders since the mid-1990’s to make our SUPER-PRECISION® lathe spindles be world class!

IMTS Demo: Advance Ceramic Grinding

The Industry: Advance Ceramic Grinding

Advance ceramics are utilized heavily within the semiconductor, aerospace, medical, defense, and other industries globally. Due to these materials’ impressive characteristics, they are becoming more prevalent, replacing products that were traditionally made from more conventional materials. With demand for advanced ceramics increasing worldwide, manufactures are looking for more efficient and capable processing solutions.

The Jones & Shipman 10 grinder is an ideal platform for production cylindrical grinding of small to midsized components.

IMTS Demo: Industry Die

The Industry: Carbide Dies & Tooling

The Hauser 2000 not only meets the demand of the market for combined grinding and hard milling on a single jig grinder, but also enables further improvements in machining precision to meet future requirements. The main technical feature is the dual-frame design, which significantly increases the rigidity of the grinder and therefore ensures even higher precision.

The new standard in ID grinding, Voumard 1000 improves the precision and productivity for the most demanding machining applications. A rigid base, hydrostatic guideways on all axis, and new user interface on our controls will deliver on your most challenging requirements.

The USACH 75 CNC cylindrical grinder delivers accuracy and power in a compact design for all production and/or universal small precision parts manufacturing where IDs, ODs and faces need grinding.

IMTS Demo: Bolt Carrier

The Industry: Gears, Camshafts, Fasteners, & Chain Parts

IMTS Demo: Aerospace

The Industry: Machine Tool Building

Aerospace is at high demand, and the Kellenberger K-10 helps simplify the even the most difficult parts. With the innovative new technology of Blue Solution this will improve not only the quality of the part, but also cut down grind time. The K-10 can hold all the tight tolerances whether it is with form grinding, dimensional tolerance, or roundness that are so critical in Aerospace.

The original standard knee mill. With over 370,000 machines built in the past 70 years and counting, the Bridgeport Series I serves in shops and industries all over the world and satisfies the demand for an accurate, reliable, and versatile mill.

IMTS Demo: Mold Making & Rapid Prototyping

The Industry: Automotive Mold

The automotive industry is constantly changing and so must the manufacturer of the parts. The XR1000 meets these demands by providing the flexibility, rigidity, and stiffness for mold manufactures to process their molds efficiently, along with the finesse to meet the specifications of mold finishes.

IMTS Demo: Tree Service Industry

The Industry: High Volume Production

Manufacturers with high production volumes are constantly looking for ways to improve machining capabilities with better spindle utilization. The XR800 APC allows manufactures to double their spindle utilization with the automated pallet changer compared to stand alone VMC’s. With the addition of automation manufacturers could potentially look to run lights out operations on the XR800APC.

IMTS Demo: Bottle Opener

The Industry: Job Shops

Manufacturers in Job Shops look for a compact versatile VMC to manufacture small parts. The XR600 provides the small footprint high versatility and functionality they are looking for. The rigid robust design with many standard options included allow Job Shops the flexibility meet their customer demands across many applications.

OTW’s VersaHone vertical cylinder honing machines are designed to be highly adaptable and easy-to-use. This honing equipment offers precision cylinder honing for a broad range of applications and is available in both single and multi-spindle configurations.

The newly named PowerHone horizontal tube honing machine features full servo control and a redesigned user interface, Allen-Bradley controls and a new, modular platform that will improve equipment order lead times by 30%. The PowerHone horizontal honing machine is offered with multiple fixturing and system options and is ideal for parts processed in the aerospace, defense, plastics and hydraulics industries.

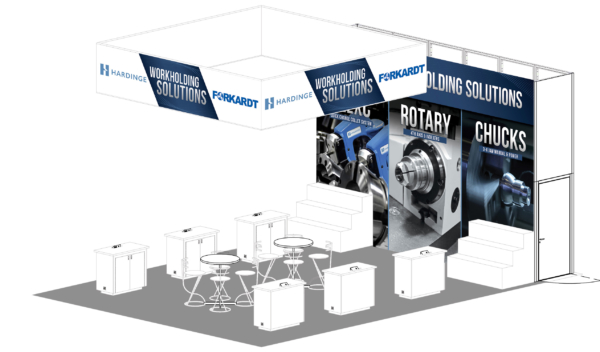

| NEW FlexC Workholding for 2022 | 32mm 52mm 100mm 120mm 140mm 160mm |

| FlexC Workholding | 42mm 65mm 80mm |

| FlexC Accessories and Adaptors | 5C; 16C; Step Chuck; Sure-Grip expanding collet adaptors Part Ejector NEW for 2022 Part Sensing and Coolant Blast Part Stops |

| Standard CNC Lathe Workholding | Standard Collets C Series J Series Emergency Collets Extended Nose Collets Step Chucks Dead Length Master Collets and Pads Custom Workholding Assorted Specially-Engineered Collets Sure-Grip® Expanding Collets |

| Swiss Workholding | Collets Carbide and Meehanite Guide Bushings Bar Loaders Tool Holders NEW for 2022 Newly designed emergency extended nose collet Meehanite Emergency Guide Bushing |

| Manual & PowerChucks | Buck |

| Screw Machine Workholding | Acme-Gridley Brown and Sharpe Davenport Index Euroturn Workholding |

| Hardinge Collet Adaptation Chucks (HCAC) | Pullback and Deadlength A2-5, A2-6, A2-8 Spindle Adaptors C Series and J Series Chucks |

| Rotary and VMC Workholding | Featured GD210LP Rotary Table Indexer with FlexC Quick-Change Collet system Collet Blocks 3C; 5C; 16C; FlexC |

Forkardt continues to be the leader in non-deforming workholding solutions with the introduction of the 200mm and 260mm 6-jaw standard pull down chucks.

The Forkardt QCS reduces setup time when changing out workholding systems on lathes. The QCS system uses the Forkardt Tru-Change geared coupling, to ensure industry-leading repeatability when changing chucks.

Developed for A2-6, A2-8, and A2-II spindle mounts, these chucks are secured using a single bolt mechanism for a quick changeover and are adaptable to any lathe suitable chucking system.

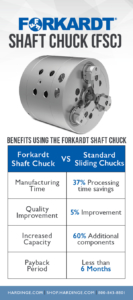

The Forkardt Shaft Chuck (FSC) allows one continuous turning operation. Its jaws are designed to extend and retract during the turning operation. Chuck jaws are extended to clamp the shaft. As the turning tool approaches the end of the workpiece, the chuck jaws retract, driving the shaft with (3) replaceable carbide drive pins or drive blades. The result is one non-interrupted, continuous turning operation.

The Forkardt product is designed to not only meet current standard designs, but in utilizing the strong engineering capabilities of Forkardt Workholding, provide custom solutions that meet or exceed current market offerings.

With an array of spindle tooling and SUPER-PRECISION® accuracy, for a total production package, the DD125 Rotary can be used with a servo control as a standalone unit or integrated with other controls. It offers no backlash with direct spindle encoder positioning feedback, an optional high-speed configuration for turning and grinding applications, up to 2,000 RPMs, A2-4 spindle nose/5C collet seat, a pneumatic closer for versatile tooling options, and more.

Forkardt is launching a high precision scroll chuck for grinding applications. The sealed chuck body, with the additional seals on the base jaws, ensures that the lubricant stays in the body and the grinding dust stays out. A KIN jaw interface and pre-machines jaws with a precision simultaneous chuck ensure the highest accuracy at the clamping point. A repeatability of <0.005 mm ensures process-reliable good workpieces.