Machine Inventory Sale

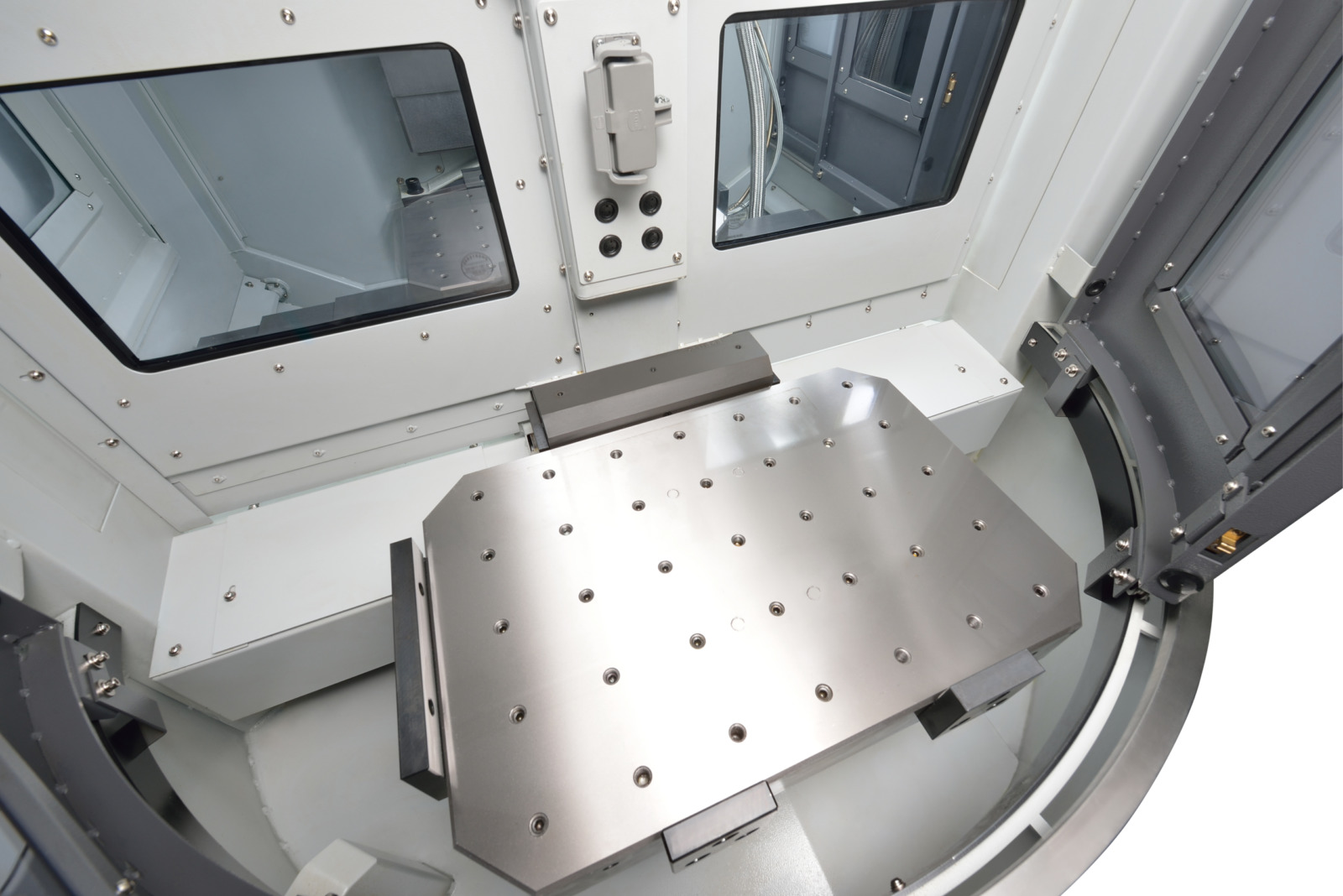

Exclusive, limited-time offers on precision CNC turning centers, milling machines, grinders, multifunction turning/grinding machines, and more. Act fast: all machines are in-stock and ready to ship!

Exclusive, limited-time offers on precision CNC turning centers, milling machines, grinders, multifunction turning/grinding machines, and more. Act fast: all machines are in-stock and ready to ship!

Complete support for all aftermarket needs.

Our diverse product portfolio enables us to support a variety of applications across the aerospace, silicon carbide, semiconductor, agricultural, automotive, construction, consumer products, defense, energy, medical, technology, and transportation industries.

Hardinge is a leading international provider of advanced metal-cutting solutions.

Hardinge has become a leader in grinding solutions with a product line encompassing Kellenberger, Voumard, Hauser, USACH, and more. With offerings across the capability spectrum, standard distance between centers of up to 63″, and special distance between centers of up to 200″, Hardinge is your partner for every grinding need.